Researchers create new textiles that don’t easily wrinkle

07/25/2018 / By RJ Jhonson

Even in engineering, a wrinkle-free textile is ideal. Researchers from the University of British Columbia (UBC) Okanagan campus are looking for ways to reduce wrinkling in producing textile composites.

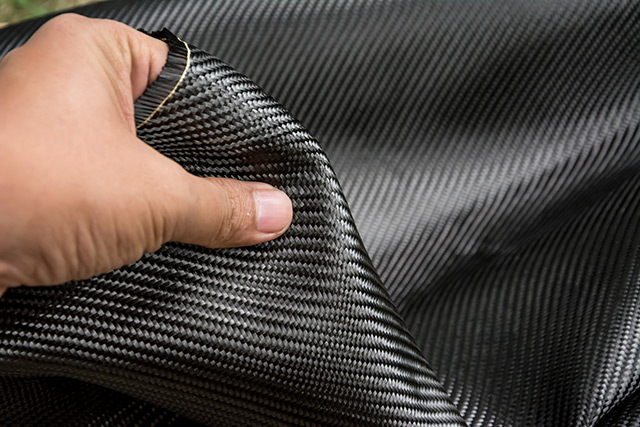

Like all composite materials, textile composites consist of a component material (often thermoplastic) or a combination of two materials reinforced with woven, knitted, or braided fabric. They are valued for their strength and durability, qualities which, incidentally, rely heavily on the integrity of the textile component.

As is the case with conventional cloth, errors in handling, production, or the material itself could cause the dry fabric in textile composites to wrinkle. Abbas Milani, a professor in UBC Okanagan’s School of Engineering and one of the researchers involved in the endeavor, says such an error could alter the final product and even reduce its strength by up to 50 percent.

Over the course of their study, the researchers looked at various ways of reducing or removing wrinkles. They discovered that pulling the material simultaneously in two directions using a custom-made biaxial fixture to stretch the fabric did the trick.

However, they admit that their method does have risks.

“The challenge was to avoid unwanted fiber misalignment or fiber rupture while capturing the out-of-plane wrinkles,” notes graduate student Armin Rashidi, another member of the research team. “Manufacturers who use these types of composites are looking for more information about their mechanical behavior, especially under combined loading scenarios.”

To prevent overstretching the fabric, they employ specialized 3D scanning and image processing technologies. These tools allow them to determine the forces required to create and remove wrinkles on the material depending on its size and shear angles.

The research was initially published in the journal Materials & Design.

Different uses for composite materials

Textile composites are finding their way toward applications where sheets of metal were previously preferred. This is thanks to their strength and longevity, as well as flexibility in design. They are not limited to just one material either, as depending on the intended use, textile composites may use yarn or plant fibers, among others. In fact, when Henry Ford first proposed the idea of what will eventually become known as textile composites, he thought of using hemp and wheat straw.

Today, textile composites are used in very specialized fields, usually in the creation of very sturdy equipment and modes of transport.

Automotives

There is always a demand for faster, sturdier, and more comfortable cars. Textile composites and other types of composite materials are making it possible to manufacture land vehicles designed to adhere to users’ exacting standards and more.

Take cars for example. More and more manufacturers are favoring composites over metal products. Carbon fiber-reinforced composites, for example, offer up to 40 percent lightweight benefits without compromising neither integrity nor freight capacity. Additionally, reductions in weight mean increases in both fuel and, in the case of electric cars, battery efficiency.

Aerospace vehicles

Modern civilian airplanes have a higher percentage of composite materials in their composition compared to older models. Textile composites offer high strength-to-weight ratios of up to 20 percent, as well as a slew of other benefits that include reduced fuel consumption, reduced emissions, enhanced aerodynamic properties, and lower production costs. Composites help military aircraft achieve increases in both speed and maneuverability.

Marine vehicles

Sea-faring vessels can’t be too heavy, so textile composites are used in many types of marine vehicles, including yachts, passenger ships, naval ships, power boats, submarines, and submersibles, among others. Racing yachts, for example, depend on composite materials to resist wave impact and enable high-velocity travel.

Learn more about newly developed materials at Inventions.news.

Sources include:

Tagged Under: aerospace, automotives, carbon fiber, carbon fiber composites, composite materials, engineering, fabric, goodtech, innovation, inventions, marine vehicles, materials, research, science and technology, textile, textile composites, wrinkle reduction, wrinkles